Signs Your Water Softener Isn’t Regenerating Properly

Water softeners play a crucial role in treating hard water, ensuring that your household appliances and plumbing systems remain free from damaging scale buildup. At the heart of this treatment process lies the regeneration cycle, a mechanism designed to effectively remove hardness minerals such as calcium and magnesium from your water supply using a process called ion exchange.

During the ion exchange process, hard water flows through a tank filled with resin beads. These beads are charged with sodium ions, which readily exchange places with hardness ions. When hard water passes through the resin beads, calcium and magnesium ions are attracted to the surfaces of the beads and replace the sodium ions, thereby softening the water. However, this process cannot sustain indefinitely, as the resin beads gradually become saturated with hardness minerals and require regeneration.

The regeneration cycle typically involves several steps: first, a brine solution composed of salt and water is introduced into the resin tank. This concentrated salt solution washes over the beads, displacing the accumulated hardness ions and recharging the beads with sodium ions. After the brine flush, the system undergoes a rinse cycle to remove any residual brine solution, ensuring that the water softener is ready to resume normal operation. The entire regeneration process usually take a few hours and occurs based on a timer or water usage patterns.

Understanding the regeneration process is vital for homeowners as it helps in recognizing signs of dysfunction within the water softening system. If the regeneration does not occur properly, it can lead to an inadequately softened water supply, resulting in potential damage to appliances and plumbing as well as an increase in hard water-related issues.

Common Signs of Poor Water Softener Performance

Homeowners rely on water softeners to effectively remove minerals like calcium and magnesium from their water supply, which can lead to hard water problems. When a water softener is not regenerating properly, various symptoms may arise, indicating a decline in performance. Identifying these signs early can prevent further issues and help maintain the efficiency of household appliances.

One of the most noticeable signs that a water softener is malfunctioning is the presence of hard water. If you start to notice hardness in your water, such as mineral deposits forming on fixtures, it may suggest that the softener is not working correctly. This is often accompanied by difficulty in producing lather with soap, requiring more soap for basic cleaning tasks, which is another indication of softener inefficiency.

Another common symptom is the accumulation of limescale on faucets and showerheads. Scale buildup can drastically reduce the lifespan of appliances and inhibit water flow, which may lead to costly repairs or replacements. If you observe scale on your dishes or within the dishwasher itself, it serves as a clear warning that your water softener may need immediate attention.

Additionally, an unexpected increase in soap usage can highlight performance issues. Homeowners may find themselves utilizing more detergent in their washing machines or dishwashers to achieve the desired cleaning results. This not only increases costs but may also indicate that the softening system is struggling to condition water effectively.

In conclusion, recognizing the symptoms of poor water softener performance—such as hard water, increased soap demands, and scale formation—can guide homeowners in addressing potential problems promptly. Regular maintenance and monitoring are essential for ensuring your water softener functions optimally, protecting both your plumbing and appliances.

Potential Causes of Regeneration Failure

The regeneration process of a water softener is critical for its optimal performance, and several factors may disrupt this essential function. First, issues with the control valve can significantly hamper the ability of the unit to regenerate effectively. The control valve regulates the flow of water during the regeneration cycle; if it becomes stuck or malfunctioning, it may prevent the proper timing or amount of water being directed through the resin bed, resulting in inadequate ion exchange.

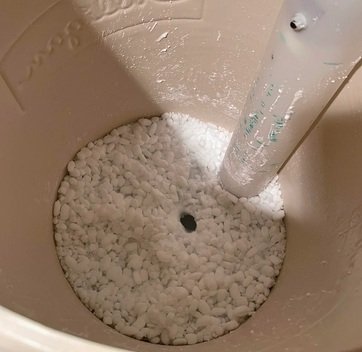

Another common issue to consider is salt bridging within the brine tank. Salt bridging occurs when a hard crust forms on top of the salt, creating a barrier that prevents the salt from dissolving completely in water. This can lead to insufficient brine during regeneration, reducing the water softener’s ability to restore the ion-exchange resin fully. Regularly inspecting the brine tank for signs of salt bridging can help mitigate this issue.

Moreover, clogged injector screens can also be a source of regeneration failure. These screens play a vital role in facilitating the flow of brine from the tank to the resin bed. Over time, debris and sediment may accumulate, obstructing the flow and impeding the regeneration process. Cleaning or replacing injector screens as part of routine maintenance can ensure smoother operation.

Additionally, power supply issues may hinder the water softener’s ability to regenerate. The unit relies on electrical signals to initiate and regulate the regeneration cycle. If there are fluctuations in power or breaks in power supply, it might result in missed regeneration cycles. Checking connections and ensuring a stable power source is essential for proper functionality.

When to Seek Professional Help

Water softeners are essential appliances that help maintain the overall quality of water in a home. However, there are instances when it is necessary to seek professional assistance regarding water softener issues. Determining when to move beyond DIY troubleshooting is crucial for effective remediation. If basic troubleshooting steps—such as checking the salt level, examining the bypass valve, or ensuring proper power supply—do not resolve the regeneration issue, it may indicate a more serious underlying problem that requires specialist intervention.

Common indications that a professional should be consulted include persistent issues with water hardness after regeneration cycles, unusual noises emanating from the system, or visible signs of leakage. It is critical not to overlook these warnings, as neglecting to address them promptly can exacerbate the issue, leading to further damage and higher repair costs.

While repair costs can vary significantly based on the severity of the problem and the specific services required, it is advisable to anticipate a range from $100 to $300 for service calls. During these visits, homeowners can expect a thorough examination of the softener system, including the control head, resin tank, and plumbing connections. Professionals generally utilize specialized tools and technologies to diagnose and rectify issues effectively.

Moreover, regular maintenance is essential to prevent regeneration problems in the future. Implementing scheduled checks can extend the lifespan of the water softener and enhance its efficiency. Ultimately, investing in professional help when necessary is vital for ensuring the ongoing performance of the water treatment system, while proactive maintenance can mitigate costly repairs down the line.