DIY Maintenance Tips for Your Water Softener

A water softener is a crucial device designed to treat hard water, which contains high levels of calcium and magnesium ions. These minerals can lead to various problems such as scale buildup in pipes and appliances, reduced effectiveness of soaps and detergents, and diminished water quality. The primary function of a water softener is to exchange these hard water ions with sodium or potassium ions, thereby softening the water that flows through your plumbing system.

The operation of a water softener typically involves several key components, including the resin tank, brine tank, and control valve. The resin tank contains the resin beads that perform the ion exchange process. As hard water enters the tank, calcium and magnesium ions attach to the resin beads, while sodium or potassium ions are released into the water. Over time, these resin beads become saturated with hardness ions, necessitating regeneration. This process involves the brine tank, where a concentrated salt solution cleans the resin beads, allowing them to resume their softening capacity.

Regular maintenance of your water softener system is essential to ensure its optimal operation and longevity. Neglecting this maintenance can lead to mineral buildup, which may impair the system’s efficiency and, ultimately, the performance of your plumbing and appliances. Furthermore, hard water can significantly reduce the lifespan of water-using devices, leading to unexpected repair costs. Thus, understanding how your water softener works and maintaining it properly can contribute to better water quality and improved appliance efficiency in your home.

Regular Maintenance Tasks for Optimal Performance

To ensure your water softener operates at peak efficiency, it is crucial to establish and adhere to a regular maintenance routine. This involves several key tasks that help prolong the lifespan of the unit and maintain the quality of your softened water. Regular checks should be performed, ideally on a monthly basis, to monitor salt levels, clean the brine tank, and inspect the resin beads.

Firstly, checking the salt levels in your brine tank is essential. It is advisable to maintain a minimum of 4 to 6 inches of salt in the tank. If you notice that the salt is low, replenish it with high-quality sodium chloride pellets or blocks to ensure effective softening. Make it a habit to check the salt levels every month and refill as necessary.

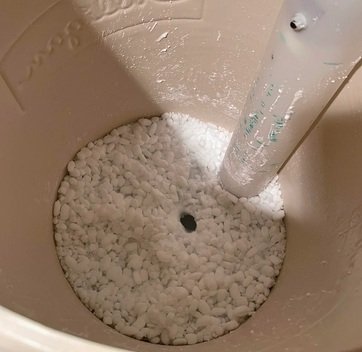

Next, cleaning the brine tank is a vital task that should be performed approximately every six months to prevent sediment buildup and ensure optimal performance. Start by unplugging the softener and draining the brine tank. Once empty, use a mixture of water and vinegar to scrub the inside surfaces. Rinse thoroughly with clean water before reassembling the unit. This simple step can significantly enhance the efficiency of the water softening process.

Finally, inspecting the resin beads, usually performed annually, ensures that they are functioning correctly. Look for any signs of wear or degradation, as damaged beads can severely impact performance. If the resin beads appear discolored or have lost their ability to soften water, consider replacing them. Document these routine maintenance tasks on a calendar or maintenance checklist to help you stay organized and ensure timely completion of each task, leading to optimal performance of your water softener.

Troubleshooting Common Issues

Homeowners may encounter several common issues with their water softeners, leading to inefficiencies in water treatment. One prevalent problem is low water pressure, which can occur for various reasons. It is essential to check the system’s filter and resin, as clogs can restrict water flow, resulting in reduced pressure. Regular maintenance and cleaning of these components may resolve the issue. Additionally, inspecting the water supply lines for kinks or obstructions can ensure that water flows freely through the system.

Another issue often reported is salt bridging, a phenomenon where salt crystals form a solid crust in the brine tank. This situation can prevent the softener from regenerating properly, leading to hard water problems. Homeowners can identify salt bridging by noticing a lack of soft water and inspecting the brine tank for an unusually hard surface. To rectify this, it may be necessary to break up the bridge manually and add fresh water to dissolve the remaining salt. Ensuring adequate regular salt levels in the tank can prevent future occurrences of bridging.

System failure is also a significant concern for many homeowners. Indicators of complete failure may include the absence of soft water and unusual noises coming from the unit. In such cases, it is crucial to examine the electrical connections and ensure that the control valve operates smoothly. If the softener still does not function correctly, checking for any software resets or error codes can provide valuable insight. For ongoing issues beyond simple maintenance, consulting a professional may be necessary to address complex repairs or replacements.

Tips for Extending the Lifespan of Your Water Softener

Proper maintenance of your water softener is crucial for ensuring its longevity and optimal performance. One of the first steps in prolonging the life of your unit is to select the right salt. The type of salt used in your water softener can have a significant impact on its efficiency and functionality. Opt for high-purity salt to minimize residue build-up, as impurities can lead to clogs and decreased performance over time. Regularly check the salt levels and replenish as necessary, keeping an eye out for any signs of bridging, which can hinder the unit’s operation.

Another important aspect of maintaining your water softener is protecting it from extreme temperatures. If your unit is located in an area that experiences significant heat or cold, consider insulating it adequately. In colder climates, freezing temperatures can damage the system, while excessive heat may lead to component wear and increased salt evaporation. Proper insulation can mitigate these risks and help maintain stable operating conditions for the softener.

Additionally, scheduling professional check-ups can result in significant long-term benefits. While regular maintenance can be handled with DIY tips, experts can assess the unit for unique issues that may not be apparent. During these check-ups, they can also clean internal components, ensuring everything operates at peak efficiency. Replacing worn-out parts, such as valves or resin, can dramatically enhance your softener’s effectiveness and reduce its energy consumption.

Finally, consider upgrading components over time. As technology advances, newer components may provide better efficiency and function. Investing in these upgrades can enhance water quality and reduce the frequency of repairs, ultimately extending the lifespan of your water softener.